Assemblies Unlimited can manage your complete blister packaging project by supplying you with in-house design, local sourcing of packaging materials, and final blister packaging assembly that will all help guarantee your product’s success at the retail level.

Since 1993, we have been providing customers with the most current and relevant blister packaging designs, our staff will coordinate every step of the process in order to make sure that your product has the right features to succeed at retail. We are a “quick-turnaround” expert, so do not be concerned about tight deadlines.

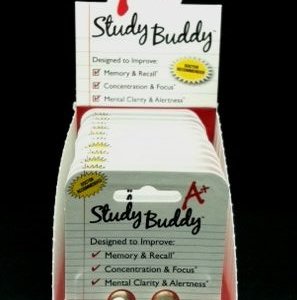

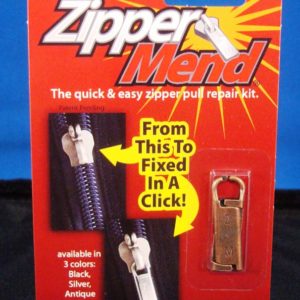

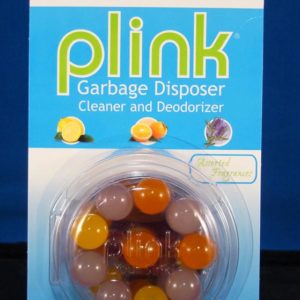

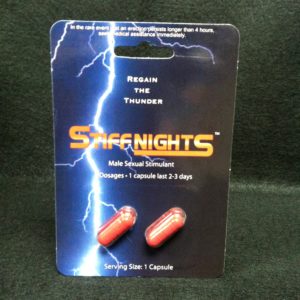

We take pride in providing the perfect, most cost-effective contract packaging solution every time. A blister package is one of the most popular methods to retail a product because it is visible behind a glossy covering and gives the consumer a full view of your product while protecting it from dirt, moisture, and theft.

Use the blister card as a “billboard” to communicate your message about the product’s use and features. Choosing the correct size blister card allows you to describe your product in detail while attracting the consumer with colorful and “catchy” graphics.

Our Blister Packaging options include:

- Face seal blister – A custom thermoformed PVC blister is heat-sealed to the front of a blister card

- Trap blister – Where the flange of the thermoformed blister is “trapped” between a front and a back blister card (or between a fold-over card)

- 2 piece blister – This is also referred to as a clamshell package where there is a front blister that matches up with a rear blister capturing a graphic card and your product in between them. The two halves can then be snapped together or sealed around the perimeter using RF technology to secure the package.

- Combination clamshell and blister – This is a hinged clamshell that encapsulates your product and then snaps closed, but it has a flange around the perimeter of the clamshell that allows it to be heat-sealed to a blister card. This style is especially beneficial for a product that requires a “re-closeable” feature. In addition, this option allows your product to be viewable from both sides of the blister card.

Blister Project features and design parameters to consider:

- Blister card size. You always want your blister card to be as small as possible, as it will play a “cost” role in the sealing part of the process. Smaller is always better, but you need to balance that with the size of the product you are blistering, making sure you leave the proper amount of card space for effective graphics on the front and back of the card, which undoubtedly helps sell your product. The thickness or caliper of a standard style blister card is typically .021 points.

- Hang Hole. Most every blister card has a die-cut hang hole. This is NOT an additional cost and is required by most retailers.

- Foot. This is a protrusion of plastic specifically designed at the base of the PVC rigid blister, allowing your final blister package to stand vertically on a store shelf. Blisters designed with a foot would still have a hang hole in the blister card.

- Minimum production runs: Our minimum run is 10K units

- Artwork. All artwork is to be supplied by our customers. We can refer a local graphic artist if you need help with art development. Art can be supplied on a disk, emailed to us, or uploaded to our FTP site. All art files should be in high-resolution Adobe Illustrator (.ai) file format. We recommend 4 colors plus any PMS colors for the front, but your least expensive printing option is to have only 1 color on the back of the card. This color should be black. Many customers prefer 4 colors on the back of the blister card, but this could double the price of the card.

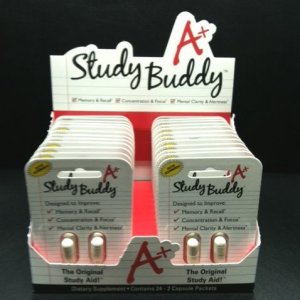

- Final Pack-Out options. Once your product is blister packaged, how do you want it packed into cartons that are shippable. Choices are master cartons (shippers), counter displays, POP displays, sidekick displays, PDQ displays, or club pack displays. We can help you determine the best option for your specific product.

- Timelines and lead times. Once you have selected a card size and your artwork is completed, we will need a “production” sample of each of the products that will go into the blister package, and we can begin custom designing and prototyping the PVC blister for sign-off. Once we have artwork, we can have your complete project blister sealed and pack out in 4 weeks or less. This includes materials AND labor.