Additional packaging steps are often needed for food or non-food projects to complete the finished goods that have already gone through the first step of primary filling or packaging. These steps are commonly referred to as “secondary” packaging.

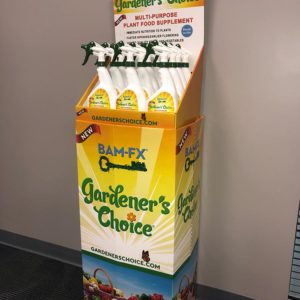

Below are some pictures of our “secondary packaging” projects completed:

The final secondary packaging steps needed to complete a project might include:

- Shrink Wrapping

- Shrink Sleeving using Steam Tunnel

- Registered Bundling with printed film

- Multi-Packs

- Club Packs

- POP Display Assembly

- Kitting

- Foil Blistering

- Card Blistering

- Clamshell RF Sealing

- Manual Assembly

- Packing Out

- Repackaging

- Relabeling

- Gluing

- Fulfillment

- and many more

Assemblies Unlimited has built a great reputation for providing “secondary” assembly and packaging processes quickly and cost-effectively. Please contact us today and provide us with the specifications for your next secondary packaging, contract packaging, or fulfillment project.

With a proven local supplier network, we can source and procure any other raw packaging materials that may be needed for your project including shrink film, blister cards, thermoformed blisters, master cases, retail chipboard cartons, pouches, flexible film and much more.

Packaging specifications needed to receive a quote on Secondary Packaging:

- Scope of work

- Step by Step assembly instructions

- Which components customer will supply and which ones you need AUI to provide

- Facility certifications required (AIB, SQF, Organic, Kosher, Halal)

- Labeling requirements

- How many finished units packed out into a case for shipping

- Date/lot code requirements for units or outer packaging

- Quantity per production run (MOQs of 25K units)

- Turnaround requirements