The process of wrapping a product in a clear or printed cellophane film is referred to as cello wrapping, or “overwrapping”. This is a high-speed operation primarily done on a high-speed horizontal form, fill, and seal machine called a Dough-Boy.

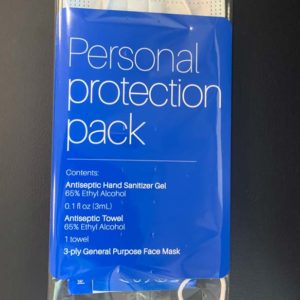

Fin-Seal overwrapping, as this packaging type is often called, is popular for sampling programs where a sample product and a coupon are overwrapped, then shipped thru a mass mailing program.

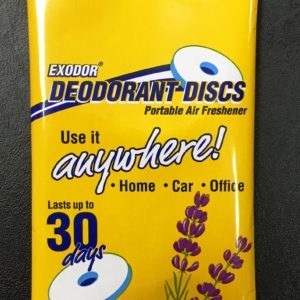

Other typical cello wrapping applications include pet treats, spice pouches, baseball cards, refills, gum, candy, treats, cosmetics and perfume, coupons, and many more. OPP film has an effective odor, moisture, and air barriers along with different thicknesses depending on the weight and type of product being packaged.

Assemblies Unlimited can source and procure clear or printed material for your contract packaging project in order to make sure the appropriate film is used for your specific project. Polypropylene film has a “crinkly” feel and a high gloss look especially when printed with bold colors.

All artwork is to be supplied by the customer in high-resolution Adobe Illustrator files. If you are considering this type of pouching for your product you should realize that it will require a fairly large minimum production run, usually around 100K units.

Information needed in order to quote a cello/overwrapping project:

- Size of product being cello wrapped

- Overall size of finished packaged

- Is a hang hole required?

- Do you prefer the end seals to be folded in the back of the pouch? (Tuck-it)

- Are you looking for a “tuck wrap” or cigarette style cello wrapping? (Perfume/Cologne)

- Are there any odors or shelf life considerations of your product?

- Do you require lot or date codes?

- How do you want the finished packaged to be packed-out? Bulk in a box?

- Do you want the film clear or printed?

- Do you have the artwork in high resolution and layered files that can be uploaded to our FTP site?