Assemblies Unlimited has been in the contract packaging industry since 1993, providing designing, assembling, and sealing custom clamshell packages.

Our knowledgeable design staff will walk you thru each step of this sometimes daunting process, including thermoforming, printing of the graphic card and final assembly, and clamshell sealing options that will work best for your specific product and clamshell solution.

As one of the best turnkey contract packaging experts in the industry, all you need to do is supply us with the product(s) you want to be packaged, along with the necessary insert card artwork files, and Assemblies Unlimited will do the rest. We will meet any tight deadlines as well as coordinate the distribution or drop shipping of your finished product.

Our Clamshell Packaging options include:

Hinged Clamshell – A custom PVC front and a back are connected by a hinge, when folded over, encapsulates your product and a graphic card which are then visible from both sides.

2-piece Clamshell – This is the same as a hinged clamshell above but without a hinge, which leaves a custom front and a custom back that get sealed together. There are benefits of this option in the assembly and sealing process.

Combination Clamshell and Blister – This is a hinged clamshell that encapsulates your product and then snaps closed, but it has a flange around the perimeter of the clamshell that allows it to be heat sealed to a blister card.

Tri-Fold Clamshell – These are hinged clamshells but have a wedge-style base that allows the product to stand vertically on a shelf. This is a very popular clamshell alternative because it will enable your unit to both hang AND stand. A Trifold clamshell is often used to package wider products.

Hybrid Clamshell – This is a way of cost-reducing a clamshell package by eliminating the higher cost of a plastic back and substituting it with a (blister) card. Example: Razor Accessories.

Club Store Clamshell – The specifications for the large club store clamshells have been redesigned and are now a trap blister with a large recyclable front and back printed blister card made from heavy stock material. Assemblies Unlimited can provide either option to any customers who are working to design a packaging solution for a club store shelf or pallet display.

Stock Clamshell – These are best used with a more generic retail product that might not require the “customization”. If interested in a standard clamshell, our minimum would be 25,000 units and Assemblies Unlimited would need to supply both the clamshell AND the labor to assemble and pack out your product.

Clamshell Packaging features and design parameters to consider:

- Overall ‘closed’ clamshell size. Thermoformed PVC clamshells are priced based on the square inch of material used so the larger the overall size of your clamshell the more expensive it will be.

- Hang Hole. Most every clamshell is designed with a hang hole. This is NOT an additional cost and is required by most retailers.

- Foot. This is a protrusion of plastic specifically designed at the base of the PVC clamshell that would allow your finished package to stand vertical on a store shelf or in a display.

- Minimum production runs: Our minimum run is 10K units.

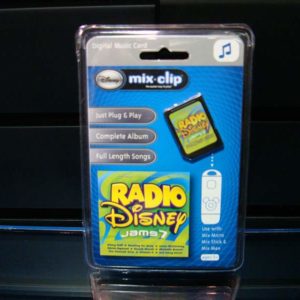

- Graphic insert card. A graphic card is part of every clamshell package as it markets the product thru text and images. All artwork is created and supplied by you. Art files can be supplied on a disk or emailed to us. All art files should be in high-resolution Adobe Illustrator (.ai) file format.

- Clamshell sealing options. Clamshells usually are designed with a flange around the perimeter of the package that is used to seal the package. Here are the most common sealing options for a clamshell:

- RF sealing (radio frequency) – This is the most popular sealing method because it is theft-proof. Units with an RF seal require that the package be opened with scissors or a knife.

- Bubble-lock – 2 halves of the clamshell are secured together by forcing the male buttons on 1 half of the clamshell into the female buttons on the other half. This is a “recloseable” feature and this option should be used for consumer products where you WANT the consumer to be able to touch and feel your product. Example: Cellular accessories.

- Perimeter “Rail” seal – A male and female “rail” that runs along the outside perimeter of both halves and then snaps together to secure.

- Final Pack-Out options. Once your product is sealed into the clamshell, there are several ways to pack out your finished units. Choices include corrugated shipping cartons, counter displays, POP displays, sidekick displays, PDQ displays, or club pack displays. We can help you determine the best option for your specific product.

- Timelines and lead times. We can start assembling your clamshell project within approximately 4 weeks after approval of color proofs and after receipt of your production samples to be packaged.