Assemblies Unlimited has been the “go-to” source for large and small Consumer Packaged Goods (CPG) companies who are looking for a proven, accessible and reliable partner. By choosing to work with Assemblies Unlimited, you will be engaging with a proven expert who will manage every step in the supply chain and onboard your project quickly and efficiently.

With a national footprint of packaging facilities, we provide a broad base of custom packaging solutions for both primary and secondary packaging, Food and Non-Food, and Liquid as well as Dry Powder filling.

In 30 years of project management experience we understand the contract packaging landscape can be confusing. Our service proposition to you is that we are great communicators, available around the clock and are easy to do business with. As turnkey specialists, we can source and procure all the raw packaging materials, manage the production process then ship the finished goods to your warehouse, 3PL or distribution point. When working with Assemblies Unlimited, our #1 goal is that you have a “Great Customer Experience”.

Please fill out the Request for Quote form on this page to receive an immediate call back from one of our experienced project managers who will go over all the packaging options for a successful program.

Food Packaging

- Powder filling

- Liquid filling

- Particulate filling

- Bottle filling

- Pouch and sachet filling

- Stick packaging

- Canister packaging

- Protein packaging

- Candy/gum filling

- Cup filling

- Carton filling

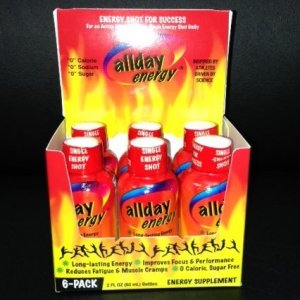

- Energy shot packaging

- Spice packaging

- VFFS Packaging

- HFFS packaging

- Primary food packaging

- Secondary food packaging

Secondary Packaging

- Shrink Wrapping

- Bundle Wrapping with registered film

- Multi-Packs

- Club Pack Assembly

- POP Display Assembly

- Kitting

- Blister Packaging

- Clamshell RF sealing

- Hand assembly

- Repackaging

- Gluing

- Warehousing & Fulfillment

- Printed Bundle wrap

- Shrink sleeve with steam tunnel

- Labeling/Re-labeling

- Cello/Flow wrapping

- Seasonal gift set assembly

Non-Food Packaging

- Powder filling

- Liquid filling

- Particulate filling

- Bottle filling

- Pouch and sachet filling

- Primary packaging

- Secondary packaging

Supplement Packaging

- Gummy Bear filling into bottles or pouches

- Tincture oil, tablets, and capsule filling into bottles and pouches

- Protein powder into bottles

- Canisters and pouches

- Liquid supplement filling into bottles and pouches

- Foil blistering of tablets and capsules

Assemblies Unlimited service proposition to our customers:

- 24-hour turnaround on quotes for projects that meet our minimums

- Full turnkey services for local sourcing and procurement of raw materials to save you money

- A dedicated inside project manager who is accessible 24/7 to champion the details and timelines of your project

- Flexibility and ease of doing business

- Multiple plant locations across the US for contract packaging, contract filling and manual assembly

- An experienced outside sales manager to guide you thru the onboarding process

- Financing arrangements for any unique equipment required for your specific program

- Fulfillment and third-party logistics support for projects requiring back-end warehousing and distribution services