Blister Packaging involves a variety of pre-formed and rigid packaging, usually PVC, primarily used for retail goods, food products, or pharmaceutical items.

Blister Packaging involves a variety of pre-formed and rigid packaging, usually PVC, primarily used for retail goods, food products, or pharmaceutical items.

The basis of blister packaging or “blister packs” is the cavity or pocket in which the product sits. This is a custom thermoformed part that can either be a symmetrical design (square, round, or rectangle) or designed to the geometry of the product it is protecting.

Depending on the type of blister packaging you are doing, the backing can be anything from foil to fiber (blister card). For the “foil” blister application, the backing is called “lidding”. A classic example of this type of packaging is cold pills that lie in the cavity and needs to be pushed through the aluminum foil for consumption. “Card” blistering is when the outer flange of a standard or custom blister is sealed to the face of a blister card.

Blister Packaging Companies

Contract packaging companies can offer clients complete blister packaging for their products, from a solid design to the blister packaging materials and the final assembly. The end goal, of course, is that the product has perfect packaging on the retail shelf for the quick “sell-thru” of the product. Contract packaging companies specialize in each step of the process, and each provides a unique capability and solution for each client, producing packaging that is just right for the client.

Why Blister Packaging?

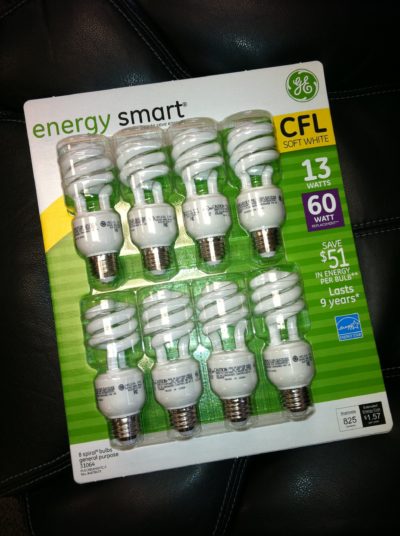

The client and consumers are pulled toward blister packaging because the product is visible through the plastic covering. This heightened visibility enables the consumer to see exactly what they are purchasing.

The gloss covering gives the product a great sense of worth, for it looks good, and the outer shell can also limit theft. The blister card size is also important because it provides important “billboard” space to describe the product and its use while attracting the customer with eye-catching images, colors, and graphics.

Blister card packaging has many other advantages in packaging as well.

How to Display Blister Packaging?

Also known as a blister pack, this type of packaging allows the consumer to see your actual product rather than a photo outside a box. Allowing the customer to view the product discourages consumers from opening the box and disrupting the packaging. This same feature makes it clearly evident if the packaging has been tampered with or if the product is otherwise damaged.

This type of packaging can also be a helpful sales tool to showcase your product and set it apart from your competitors’ product packaging. Though one of the main features of a blister package is its clear material, it can be customized with your choice of graphics on the paperboard which is attached to the blister pack.

This type of packaging can also be a helpful sales tool to showcase your product and set it apart from your competitors’ product packaging. Though one of the main features of a blister package is its clear material, it can be customized with your choice of graphics on the paperboard which is attached to the blister pack.

Another reason that blister packaging is popular in a retail setting is that it’s easy to display. A punched hang hole enables it to be hung rather than shelved. Products with a hang hole do great in a POP display, which can be a bonus to retailers. And if retailers hang the package near a checkout counter, impulse buyers will most likely boost your sales.

Blister Packaging Has Options

Also called a bubble pack, blister packaging comprises pre-formed plastic packaging that molds around the product. The front is molded plastic that keeps the product in place, and the backing is often flat paperboard. The two are heat sealed together to form a secure bond that will protect the product during shipping and sales, but that is easily opened by the consumer (unlike its cousin, clamshell packaging).

Blister packs are commonly used for battery packaging and pen packages. Blister packaging is also easily recognizable for its use in pharmaceuticals where the pills are suspended in clear material and backed with a foil or two-layer foil and paper backing.

Trap blister packages have two sides of clear material that are molded to the product. The surrounding flat edges are sandwiched between the paperboard. Other options allow the product to be sealed with RF sealing to deter theft and re-sealable two-sided hinged packaging.

Regardless of which type of blister pack you choose, there’s no denying its ability to effectively showcase your product and get it into the hands of consumers.

Packaging Considerations

When considering the best blister packaging options, there are certain things to consider in deciding how the packaging will look while always being mindful of lower costs. The size of the packaging, especially the blister card, is a high consideration, balancing how much information and graphics the clients want or need on the blister card.

Also, a larger card will reduce the number “up” on the blister tooling, increasing sealing costs. Another item is how it will be displayed, whether it will be hung on a plan-o-gram (card would require a hang hole) or whether it will stand on a shelf, thus requiring a “foot” designed into the base of the blister.

The quantity of your production run is important and will be a major factor in the final pricing of your project. Another item to consider is the quality of the artwork or graphics which will be displayed on the blister card. A good graphic artist who knows retail and understands the color wheel is worth his weight in gold!

A good contract packaging company will then, along with the client, determine final pack-out options once the blister package is designed. Some options include counter displays, PDQs, club packs, twin packs, multi-packs, floor displays, and point of purchase (POP) displays, to name a few.

Assemblies Unlimited is ready to discuss your blister packaging project. Simply request a quote or give us a call to speak with a packaging specialist.

I wasn’t too knowledgeable of blister packaging designs. Thanks very much for sharing the in-depth knowledge!